AI Video Counting & Quality Control for Industrial Conveyors

Achieve 99.9% accuracy using Computer Vision. Cost-effective automation for food, pharma, and manufacturing — works with your existing IP cameras.

Camcontador is an AI-powered solution for automated product counting and quality control on industrial conveyor lines.

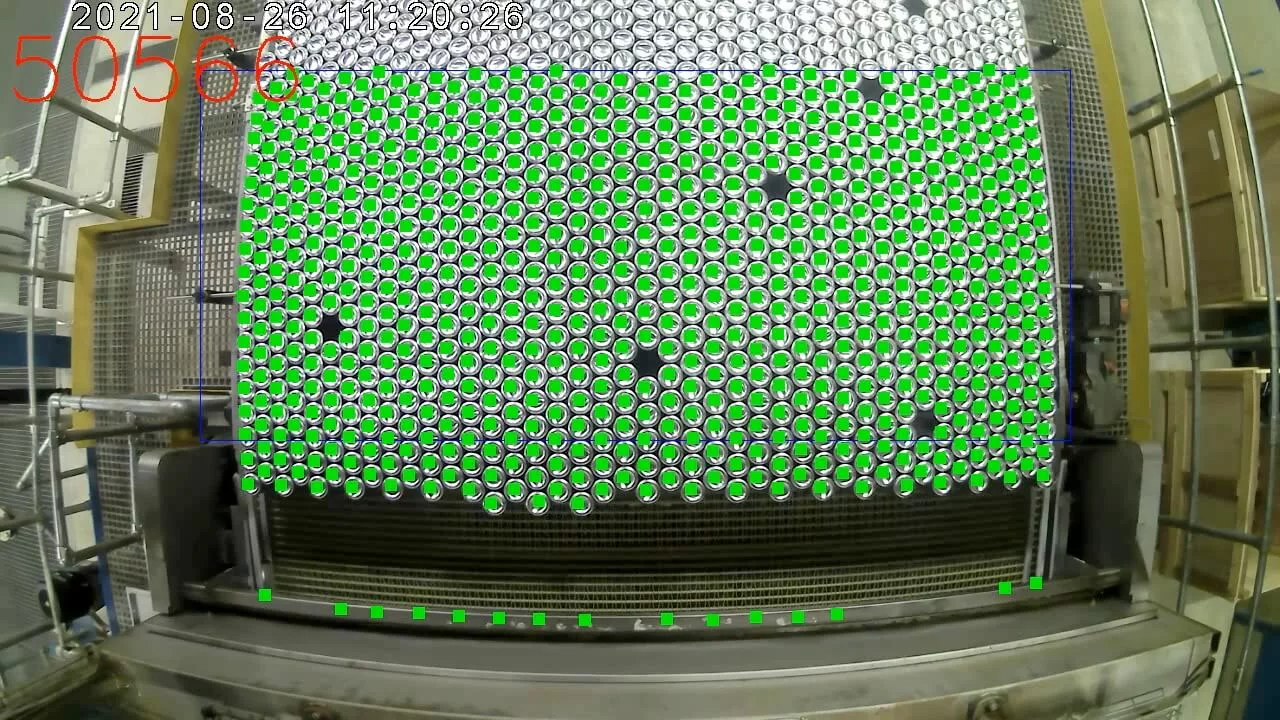

Using computer vision and object detection, the system accurately counts products in real time directly from standard video cameras — without physical sensors or changes to existing equipment.

Camcontador is designed for manufacturing, food processing, packaging, and logistics environments where reliable production monitoring, real-time data, and operational transparency are critical.

Developed and Engineered in Spain. Global support and implementation

Universal AI Solution for Counting and Visual Inspection

No lighting or angle requirements

To count products, you don’t need to change the lighting in the shop, buy new cameras, hang them at a certain distance from the conveyor belt and adjust the angle. A simple picture is enough, the products on which can be counted by a person.

Counting accuracy up to 99.9%

Unlike infrared or laser sensors, CamContador can accurately count products even when they are positioned chaotically on the conveyor. The counting error is extremely low, with an accuracy of 99.7–99.9%. You always know exactly how much product was produced — without any manual rechecking.

Camcontador is simpler and cheaper

Camcontador is more cost-effective than other counting solutions that require specialized equipment. Due to computer vision technology and the elimination of unnecessary equipment, we save the implementation budget by 3-5 times.

Free testing before implementation

Before signing the contract, we will train the video counter on your videos and show the preliminary result. If the algorithm fails, we will honestly tell you about it before we start working.

Money Back Guarantee

If after implementing the counter you are not satisfied with its work, we will refund your money. No conditions.

Advanced Features for Production Line Monitoring

- Instant Foreign Object Detection

Our video counter automatically spots anything that doesn’t belong on your line — from small fragments to unexpected objects. This ensures clean, safe production and minimizes the risks associated with manual inspection.

- High-Precision Visual Quality Control

The system continuously monitors product appearance and flags even the smallest defects: scratches, tears, stains, contamination, or surface irregularities. You get fast, consistent, and reliable quality control across the entire shift.

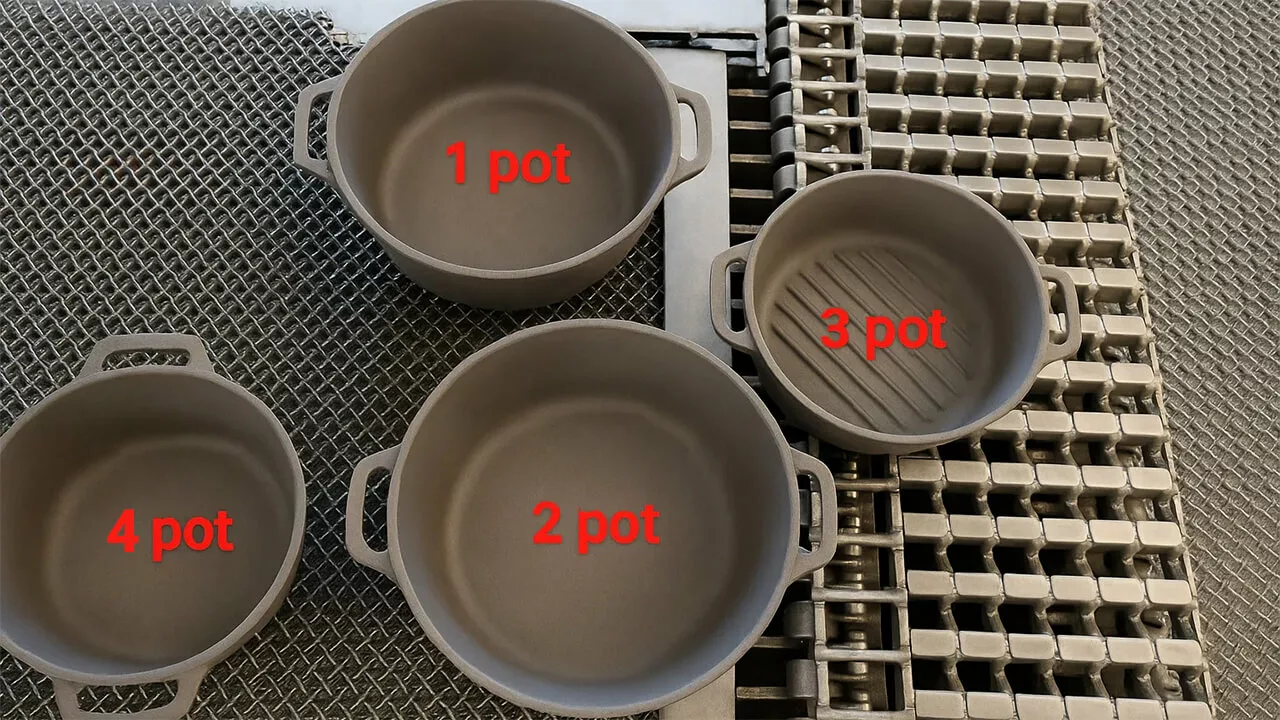

- Smart Classification and Identification

Color, shape, type, size — the video counter detects and classifies products based on the parameters you define. It instantly highlights anomalies and notifies the operator when something falls outside your standards.

- Accurate Label and Marking Verification

Ensure every label is correctly placed, readable, and matches your formatting requirements. The system helps catch marking issues early, preventing costly repackaging and customer complaints.

- Automated Sorting and Rejection

The video counter acts as an intelligent sorting unit, directing products to the right workflow and removing items that don’t meet quality criteria. This helps maintain a stable, predictable level of product quality with minimal manual effort.

- Real-Time Line Load Optimization

Get full visibility into the movement and density of products on your conveyor. The system identifies gaps, clusters, and irregular flow so you can prevent equipment slowdowns, optimize line speed, and keep production running smoothly.

AI-powered Solutions for Any Production Line

Camcontador is developed and used in real production environments, including food processing, packaging and manufacturing lines.

Our system has been tested on real conveyor belts with varying speeds, lighting conditions and product shapes.

Implementation Results

Identifying defects without manual labor

The algorithm understands what good quality products look like and does not count rejects. This includes non-standard cases: missing products in a row, smaller products, products in upside down position, chipped or unpainted products.

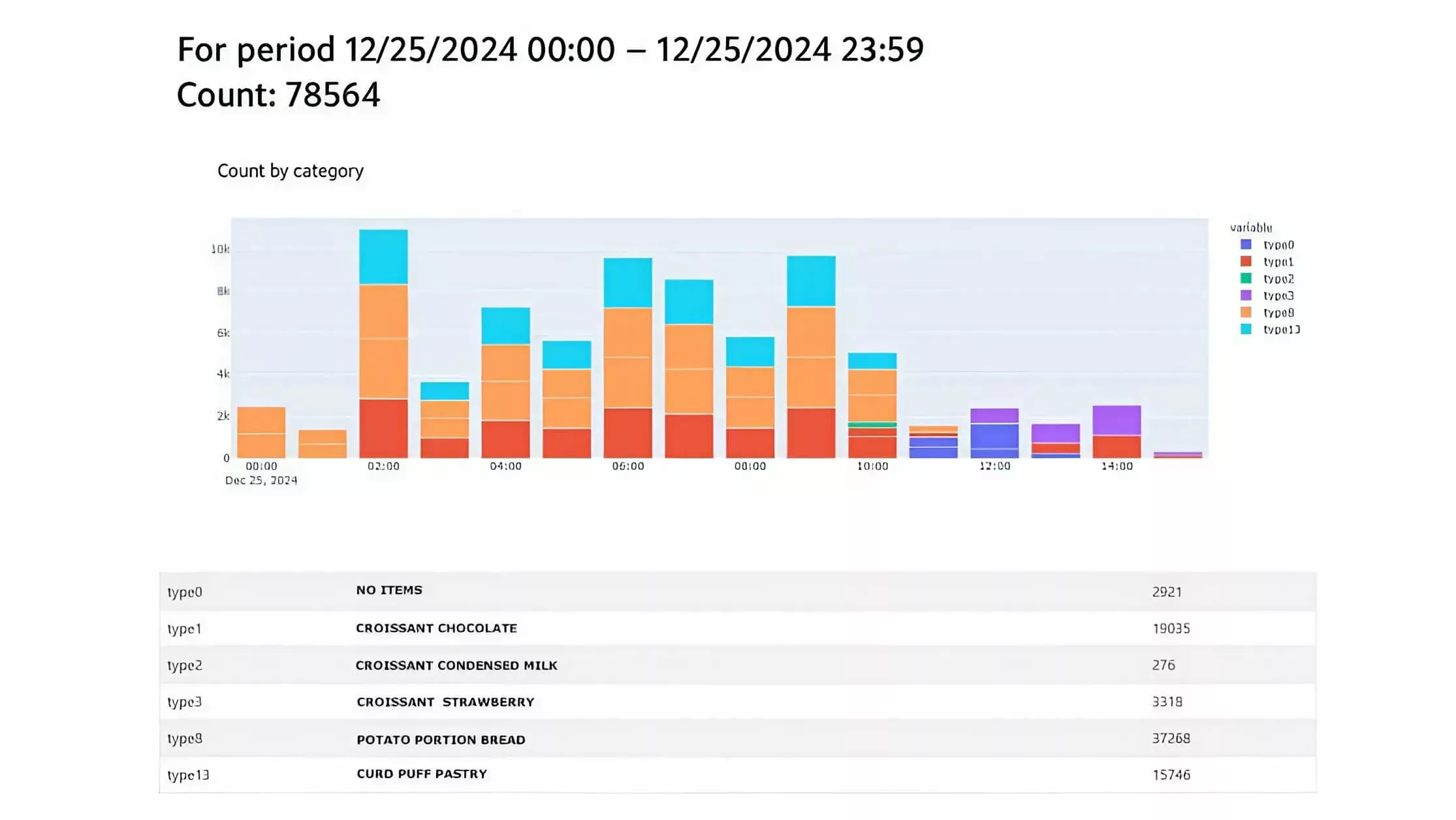

Reliable and convenient reporting

Clear graphs help to control the exact volume of output. Counting of manufactured products takes place for any period of time: shift, day, week, month. The information is transferred to ERP-system, database, Excel or text file. Such statistics is necessary for accountants and controllers at production facilities

Accurate product recognition

If there are different types of products on the conveyor, the counter will recognize them and count them separately. In addition, you can specify the type of products manually or by means of a QR code in the frame.

Technical Advantages of CamContador AI Counter

- Integrates easily with Excel and ERP systems

- Works without internet and video capture cards

- No need to change the lighting on the production floor

- No need to re-hang cameras from a different angle

- No need for hard disks to store video

- Once set up, always works

Proven in Real Production Environments

Built on Real Industrial Experience

Camcontador systems are developed and deployed on real industrial conveyor lines, operating under continuous production conditions.

Our software has been tested with different product shapes, speeds, and lighting conditions to ensure stable, accurate, and reliable operation in actual manufacturing environments.

Expert Computer Vision Technology

Our product counting solutions are powered by advanced AI and computer vision algorithms, specifically designed for industrial automation and quality control.

The system performs real-time detection, classification, and monitoring of products, ensuring precise counting under diverse production conditions.

Trusted by Industrial Applications

Camcontador is used in multiple industrial production scenarios where accuracy and reliability are critical.

Our focus on measurable results and transparent performance metrics builds long-term trust with clients across manufacturing, food processing, and packaging lines.

Reliable and Secure

Camcontador operates on secure infrastructure and follows industry best practices for data handling and system maintenance.

All systems are designed for 24/7 continuous operation, with professional support, clear documentation, and long-term maintenance options to ensure consistent and reliable production monitoring.

Real-World Use Cases

Discover how Camcontador is applied in real industrial production environments to automate product counting, improve quality control, and provide actionable data for production lines.

Implementation Examples on Production Lines

[{"id":2513,"link":"https:\/\/camcontador.com\/bread-counters-in-production-facilities\/","name":"bread-counters-in-production-facilities","thumbnail":{"url":false,"alt":false},"title":"AI-Driven Bread Counting: Automating Bakery Production Lines with Computer Vision","postMeta":[],"author":{"name":"Dmitriy","link":"https:\/\/camcontador.com\/author\/dmitriynb\/"},"date":"Jan 23, 2026","dateGMT":"2026-01-23 16:46:56","modifiedDate":"2026-01-23 18:25:16","modifiedDateGMT":"2026-01-23 18:25:16","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>","space":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>"},"taxonomies":{"post_tag":"","language":"<a href='https:\/\/camcontador.com\/' rel='language'>English<\/a>","post_translations":"<a href='https:\/\/camcontador.com\/?taxonomy=post_translations&term=pll_69750dfc5ef17' rel='post_translations'>pll_69750dfc5ef17<\/a>"},"readTime":{"min":11,"sec":34},"status":"publish","excerpt":""},{"id":2463,"link":"https:\/\/camcontador.com\/real-time-can-counting\/","name":"real-time-can-counting","thumbnail":{"url":false,"alt":false},"title":"AI-Powered Real-Time Can Counting: Computer Vision Case Study","postMeta":[],"author":{"name":"Dmitriy","link":"https:\/\/camcontador.com\/author\/dmitriynb\/"},"date":"Jan 21, 2026","dateGMT":"2026-01-21 16:39:15","modifiedDate":"2026-01-23 17:50:57","modifiedDateGMT":"2026-01-23 17:50:57","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>","space":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>"},"taxonomies":{"post_tag":"","language":"<a href='https:\/\/camcontador.com\/' rel='language'>English<\/a>","post_translations":"<a href='https:\/\/camcontador.com\/?taxonomy=post_translations&term=pll_6971481adaa64' rel='post_translations'>pll_6971481adaa64<\/a>"},"readTime":{"min":7,"sec":51},"status":"publish","excerpt":""},{"id":2431,"link":"https:\/\/camcontador.com\/product-quality-control-in-manufacturing\/","name":"product-quality-control-in-manufacturing","thumbnail":{"url":false,"alt":false},"title":"Product quality control in manufacturing: how computer vision works in real workshops","postMeta":[],"author":{"name":"Dmitriy","link":"https:\/\/camcontador.com\/author\/dmitriynb\/"},"date":"Dec 30, 2025","dateGMT":"2025-12-30 18:51:23","modifiedDate":"2026-01-23 17:51:27","modifiedDateGMT":"2026-01-23 17:51:27","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>","space":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>"},"taxonomies":{"post_tag":"","language":"<a href='https:\/\/camcontador.com\/' rel='language'>English<\/a>","post_translations":"<a href='https:\/\/camcontador.com\/?taxonomy=post_translations&term=pll_695426ec49610' rel='post_translations'>pll_695426ec49610<\/a>"},"readTime":{"min":10,"sec":46},"status":"publish","excerpt":""},{"id":2355,"link":"https:\/\/camcontador.com\/quick-and-accurate-counting-of-utensils-spoons-forks-and-knives\/","name":"quick-and-accurate-counting-of-utensils-spoons-forks-and-knives","thumbnail":{"url":false,"alt":false},"title":"Quick and accurate counting of Utensils - spoons, forks and knives","postMeta":[],"author":{"name":"iuser","link":"https:\/\/camcontador.com\/author\/iuser\/"},"date":"Nov 18, 2025","dateGMT":"2025-11-18 22:12:04","modifiedDate":"2026-01-23 17:51:42","modifiedDateGMT":"2026-01-23 17:51:42","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>","space":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>"},"taxonomies":{"post_tag":"","language":"<a href='https:\/\/camcontador.com\/' rel='language'>English<\/a>","post_translations":"<a href='https:\/\/camcontador.com\/?taxonomy=post_translations&term=pll_6923662caef0a' rel='post_translations'>pll_6923662caef0a<\/a>"},"readTime":{"min":5,"sec":56},"status":"publish","excerpt":""},{"id":2254,"link":"https:\/\/camcontador.com\/recognition-of-cans\/","name":"recognition-of-cans","thumbnail":{"url":false,"alt":false},"title":"Recognition of Upside-Down Cans with Conveyor Line Stop","postMeta":[],"author":{"name":"Dmitriy","link":"https:\/\/camcontador.com\/author\/dmitriynb\/"},"date":"Sep 30, 2025","dateGMT":"2025-09-30 13:34:13","modifiedDate":"2026-01-23 17:51:59","modifiedDateGMT":"2026-01-23 17:51:59","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>","space":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>"},"taxonomies":{"post_tag":"","language":"<a href='https:\/\/camcontador.com\/' rel='language'>English<\/a>","post_translations":"<a href='https:\/\/camcontador.com\/?taxonomy=post_translations&term=pll_68dbdc55b7e40' rel='post_translations'>pll_68dbdc55b7e40<\/a>"},"readTime":{"min":5,"sec":19},"status":"publish","excerpt":""},{"id":2147,"link":"https:\/\/camcontador.com\/counting-eggs-controlling-conveyor\/","name":"counting-eggs-controlling-conveyor","thumbnail":{"url":false,"alt":false},"title":"Egg production plant: counting eggs and controlling conveyor speed using the CamContador video counter","postMeta":[],"author":{"name":"Dmitriy","link":"https:\/\/camcontador.com\/author\/dmitriynb\/"},"date":"Jul 11, 2025","dateGMT":"2025-07-11 10:26:26","modifiedDate":"2026-01-23 17:52:14","modifiedDateGMT":"2026-01-23 17:52:14","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>","space":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>"},"taxonomies":{"post_tag":"","language":"<a href='https:\/\/camcontador.com\/' rel='language'>English<\/a>","post_translations":"<a href='https:\/\/camcontador.com\/?taxonomy=post_translations&term=pll_6870ef205cd5c' rel='post_translations'>pll_6870ef205cd5c<\/a>"},"readTime":{"min":6,"sec":8},"status":"publish","excerpt":""},{"id":1529,"link":"https:\/\/camcontador.com\/100-accurate-bread-counting-and-conveyor-control-by-video-camera\/","name":"100-accurate-bread-counting-and-conveyor-control-by-video-camera","thumbnail":{"url":false,"alt":false},"title":"100% accurate bread counting and conveyor control by video camera","postMeta":[],"author":{"name":"iuser","link":"https:\/\/camcontador.com\/author\/iuser\/"},"date":"Apr 20, 2025","dateGMT":"2025-04-20 14:17:29","modifiedDate":"2026-01-23 17:52:29","modifiedDateGMT":"2026-01-23 17:52:29","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>","space":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>"},"taxonomies":{"post_tag":"","language":"<a href='https:\/\/camcontador.com\/' rel='language'>English<\/a>","post_translations":"<a href='https:\/\/camcontador.com\/?taxonomy=post_translations&term=pll_680502956226e' rel='post_translations'>pll_680502956226e<\/a>"},"readTime":{"min":9,"sec":13},"status":"publish","excerpt":""},{"id":1402,"link":"https:\/\/camcontador.com\/egg-counting-in-a-poultry-farm-14-production-units-114-cameras-and-207-counting-zones\/","name":"egg-counting-in-a-poultry-farm-14-production-units-114-cameras-and-207-counting-zones","thumbnail":{"url":false,"alt":false},"title":"Egg counting in a poultry farm: 14 production units, 114 cameras and 207 counting zones","postMeta":[],"author":{"name":"iuser","link":"https:\/\/camcontador.com\/author\/iuser\/"},"date":"Nov 23, 2024","dateGMT":"2024-11-23 12:00:00","modifiedDate":"2026-01-23 17:52:46","modifiedDateGMT":"2026-01-23 17:52:46","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>","space":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>"},"taxonomies":{"post_tag":"","language":"<a href='https:\/\/camcontador.com\/' rel='language'>English<\/a>","post_translations":"<a href='https:\/\/camcontador.com\/?taxonomy=post_translations&term=pll_67b604b0d47cf' rel='post_translations'>pll_67b604b0d47cf<\/a>"},"readTime":{"min":7,"sec":8},"status":"publish","excerpt":""},{"id":1395,"link":"https:\/\/camcontador.com\/how-we-set-up-bread-counting-and-recognition-on-the-conveyor-belt-with-a-video-camera\/","name":"how-we-set-up-bread-counting-and-recognition-on-the-conveyor-belt-with-a-video-camera","thumbnail":{"url":false,"alt":false},"title":"How we set up bread counting and recognition on the conveyor belt with a video camera","postMeta":[],"author":{"name":"iuser","link":"https:\/\/camcontador.com\/author\/iuser\/"},"date":"Jun 2, 2024","dateGMT":"2024-06-02 12:00:00","modifiedDate":"2026-01-23 17:53:04","modifiedDateGMT":"2026-01-23 17:53:04","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>","space":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>"},"taxonomies":{"post_tag":"","language":"<a href='https:\/\/camcontador.com\/' rel='language'>English<\/a>","post_translations":"<a href='https:\/\/camcontador.com\/?taxonomy=post_translations&term=pll_67b5fbf3d1b11' rel='post_translations'>pll_67b5fbf3d1b11<\/a>"},"readTime":{"min":7,"sec":7},"status":"publish","excerpt":""},{"id":1388,"link":"https:\/\/camcontador.com\/bread-detection-classification-and-counting-at-the-oven-exit\/","name":"bread-detection-classification-and-counting-at-the-oven-exit","thumbnail":{"url":false,"alt":false},"title":"Bread Detection, Classification and Counting at the oven exit","postMeta":[],"author":{"name":"iuser","link":"https:\/\/camcontador.com\/author\/iuser\/"},"date":"Dec 14, 2023","dateGMT":"2023-12-14 12:00:00","modifiedDate":"2026-01-23 17:53:21","modifiedDateGMT":"2026-01-23 17:53:21","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>","space":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>"},"taxonomies":{"post_tag":"","language":"<a href='https:\/\/camcontador.com\/' rel='language'>English<\/a>","post_translations":"<a href='https:\/\/camcontador.com\/?taxonomy=post_translations&term=pll_67b5f2c25be8c' rel='post_translations'>pll_67b5f2c25be8c<\/a>"},"readTime":{"min":2,"sec":44},"status":"publish","excerpt":""},{"id":1363,"link":"https:\/\/camcontador.com\/video-egg-counter-in-a-poultry-farm-with-99-9-accuracy\/","name":"video-egg-counter-in-a-poultry-farm-with-99-9-accuracy","thumbnail":{"url":false,"alt":false},"title":"Video egg counter in a poultry farm with 99.9% accuracy","postMeta":[],"author":{"name":"iuser","link":"https:\/\/camcontador.com\/author\/iuser\/"},"date":"Jun 8, 2023","dateGMT":"2023-06-08 12:00:00","modifiedDate":"2026-01-23 17:53:36","modifiedDateGMT":"2026-01-23 17:53:36","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>","space":"<a href=\"https:\/\/camcontador.com\/category\/cases\/\" rel=\"category tag\">Cases<\/a>"},"taxonomies":{"post_tag":"","language":"<a href='https:\/\/camcontador.com\/' rel='language'>English<\/a>","post_translations":"<a href='https:\/\/camcontador.com\/?taxonomy=post_translations&term=pll_67b5072a9649d' rel='post_translations'>pll_67b5072a9649d<\/a>"},"readTime":{"min":1,"sec":36},"status":"publish","excerpt":""}]

What customers are saying

Andrew Fedot“Superb product and counting accuracy!”

Ball Corporation

Got questions?