Conveyor belts are widely used in many industries for material handling and transportation. One important component of a conveyor system is a product counter, which is used to track the number of items passing through the belt. There are several types of product counters available, each with their own unique features and benefits.

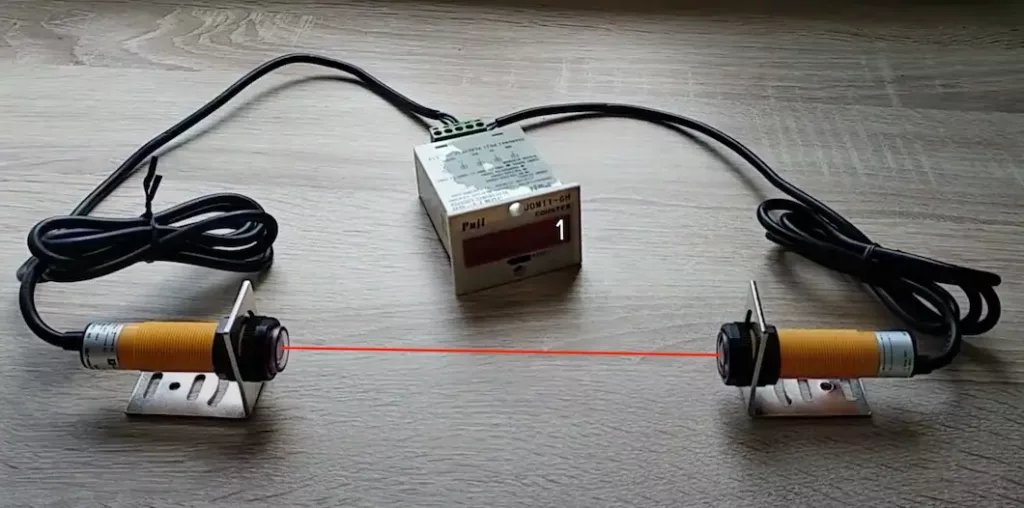

1. Photoelectric Counters

These counters use infrared light beams to detect the presence of items on the conveyor belt. When an item breaks the light beam, the counter increments. Photoelectric counters are fast, accurate, and suitable for counting small and light items.

2. Proximity Sensors

Proximity sensors are similar to photoelectric counters, but they use an electromagnetic field to detect the presence of items. These counters are more rugged and suitable for harsh industrial environments.

3. Tachometric Counters

Tachometric counters use a tachometer to detect the speed of the conveyor belt. By determining the speed, the counter can calculate the number of items passing through the belt. Tachometric counters are ideal for counting heavy and irregular shaped items.

4. Ultrasonic Counters

Ultrasonic counters use high-frequency sound waves to detect the presence of items on the conveyor belt. They are suitable for counting small and light items and are particularly useful in dusty or dirty environments where other types of counters may fail.

5. Weight Sensors

Weight sensors are used to measure the total weight of items on the conveyor belt. These counters are ideal for counting heavy items and are used in applications such as material weighing and batching.

In conclusion, product counters are an essential component of conveyor systems. Different types of product counters are available, each with its own unique features and benefits. Choose the right type of product counter based on your specific application requirements to ensure accurate and efficient material handling.

What are the pros and cons of each type of counter?

Each type of product counter has its own pros and cons, and choosing the right one for a specific application depends on various factors such as the type of items being counted, the conveyor speed, the environment, etc. Here are the pros and cons of each type of counter:

Photoelectric Counters

Pros: Fast, accurate, and suitable for counting small and light items.

Cons: May not be suitable for harsh industrial environments and may be affected by dust and debris.

Proximity Sensors

Pros: Rugged and suitable for harsh industrial environments.

Cons: May not be as fast and accurate as photoelectric counters.

Tachometric Counters

Pros: Ideal for counting heavy and irregular-shaped items.

Cons: May not be suitable for fast-moving conveyor belts.

Ultrasonic Counters

Pros: Suitable for counting small and light items in dusty or dirty environments.

Cons: May not be as accurate as other types of counters and may be affected by background noise.

Weight Sensors

Pros: Ideal for counting heavy items and for material weighing and batching applications.

Cons: May not be suitable for counting small or light items and may require additional calibration.

It’s important to evaluate the specific needs of each application and choose the right product counter accordingly.