Bread Detection, Classification and Counting at the oven exit

The client is a large bakery that produces 13 types of bread. The company has 200 employees.

Task

Make the calculation of bread at the oven exit, make the process cheaper and more accurate.

Result

The client began to use computer vision – artificial intelligence recognizes different types of bread and counts their numbers. The accuracy of calculations has increased to 99.8%, the camera counts around the clock, does not require wages, and does not get tired.

Situation

The client contacted CamContador with a request to automate the counting of bakery products using a video camera. The factory produces several tons of bread per day. Previously, products were counted manually, but the results were unsatisfactory.

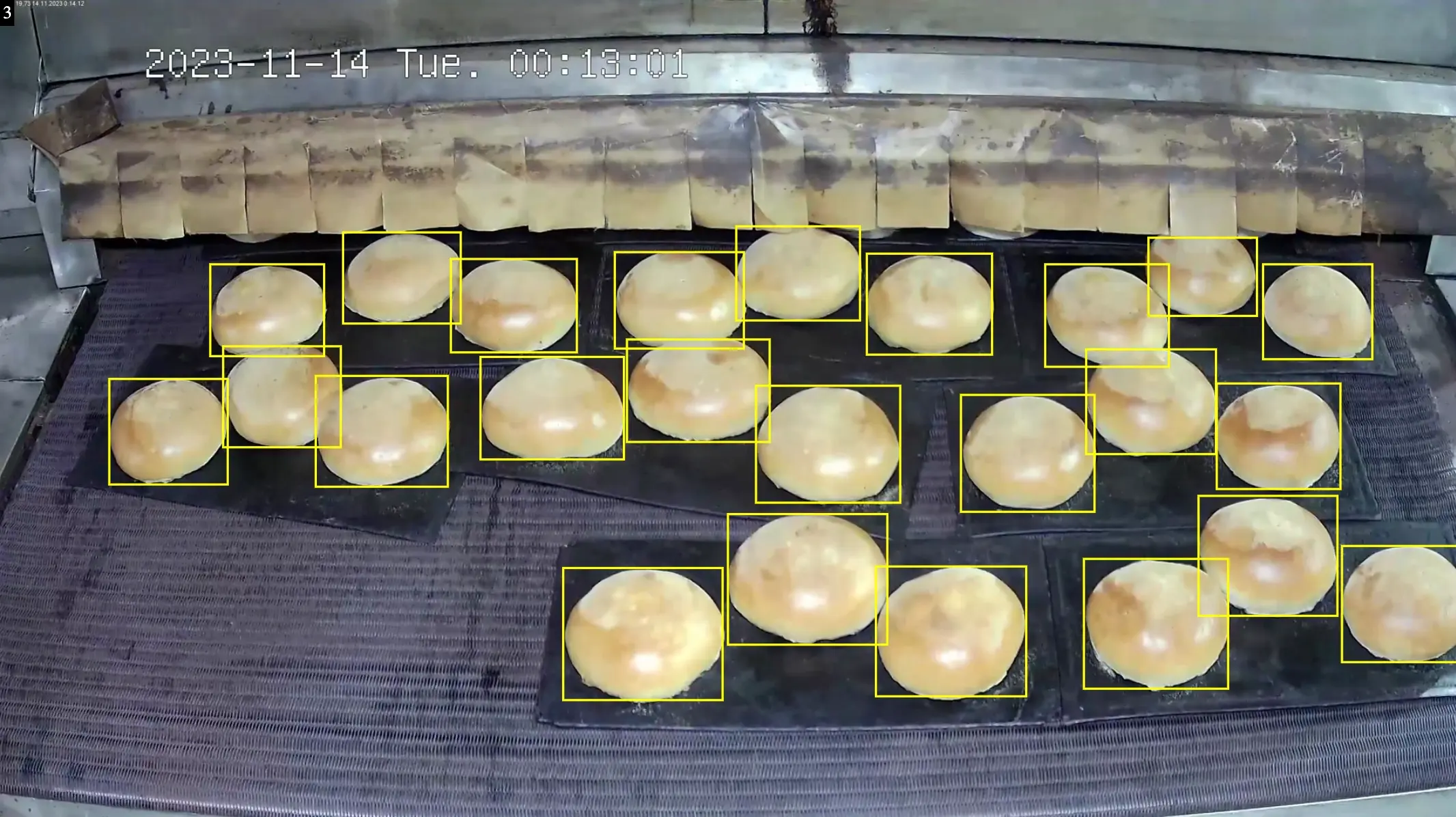

The movement of bread along the conveyor is uneven, often the products lie close to each other, so the camera was hung as vertically as possible above the oven exit.

Solution

Stage 1. Recording video in production to train algorithms

The client recorded a video of a conveyor belt along which several types of products are moving.

Stage 2. Data labeling and neural network training

We taught the algorithm to recognize different types of bread on video. On the still frames, each type of bread is manually labelled with a box:

Then the neural network is trained, after which the machine recognizes and counts different types of bread automatically. Algorithms for error-free tracking of the movement of each product unit in the video are a unique development of our engineers.

We had already worked with bakeries before, so part of the project was implemented by analogy with the previous ones. This client’s request was more complex: not just to count, but also to recognize what type of product is currently on the production line, to record in the log not just time and quantity, but also the type of product.

Stage 3. Detection of bread in production

The client installed the equipment:

- an IP-camera with a view of the conveyor belt,

- computer with Nvidia RTX 4070 12 Gb video card (It should be noted that an Nvidia GTX 1660 8 Gb would be enough for such a task.)

CamContador specialists remotely installed recognition and counting software on the client’s computer.

We labeled the data, trained a neural network (model) and uploaded the model to the client’s computer, after which the computer vision technology began to independently recognize and count bread on the conveyor belt.

After several days, it turned out that the machine made mistakes in some cases, so we labeled new images with such cases and re-trained the neural network. After several iterations there are practically no errors left.

Result

Previously, the company had employees working for this task. The cost of the wage fund amounted to 8000 € in year.

The cost of installing a smart counter per line amounted to 1350 €:

— CamContador’s services 900 €.

— Purchase of a video card 450 €.

— The client already had a video camera and a computer, so didn’t have to buy them.

This is a one-time investment – in the future the client will only need to maintain the functionality of the hardware.

The counting accuracy 99.8%.

Savings over the next three years – 24 000 €.