How to count eggs on a poultry farm

Accurate recording of all eggs produced in commercial poultry farms is a mandatory element that improves business performance and profitability. But it is not just the overall count that is important, but the count of eggs in the context of each battery. Daily monitoring of egg counts on every battery and tier allows chicken farms to detect and identify problems promptly.

Accurate recording of all eggs produced in commercial poultry farms is a mandatory element that improves business performance and profitability. But it is not just the overall count that is important, but the count of eggs in the context of each battery. Daily monitoring of egg counts on every battery and tier allows chicken farms to detect and identify problems promptly.

A decrease in egg production may be due to breakages in the automatic feeding system or watering system or manure removal system or environmental control system. So to ensure the health, productivity, and welfare of the chickens, detailed counting is vital.

A traditional way of counting eggs is with the infrared electronic egg sensors. But many of our customers come to us for computer vision egg counting technology. According to them, optical sensors make many errors and need frequent maintenance or replacement. While modern vision based egg counters can work for years without being cleaned. Because the camera lens is relatively far from the conveyor belt. They work on any size belt, elevator, or rod conveyor. Capable of counting both white and brown eggs without any adjustments. If desired, a camera-based counter can not only count, but also distinguish an egg from a chicken feather, or a dirty egg.

Battery cages are the most widely used method for housing chickens in large-scale egg production. A key component of these systems is the automatic egg collection mechanism, which usually consists of conveyor belts or trays that move the eggs from the cages to a central collection area. There are various automated egg collection systems available for battery cages, each differing in how they handle eggs between the tiers. Our solution is compatible with all of these methods. Here are a few examples.

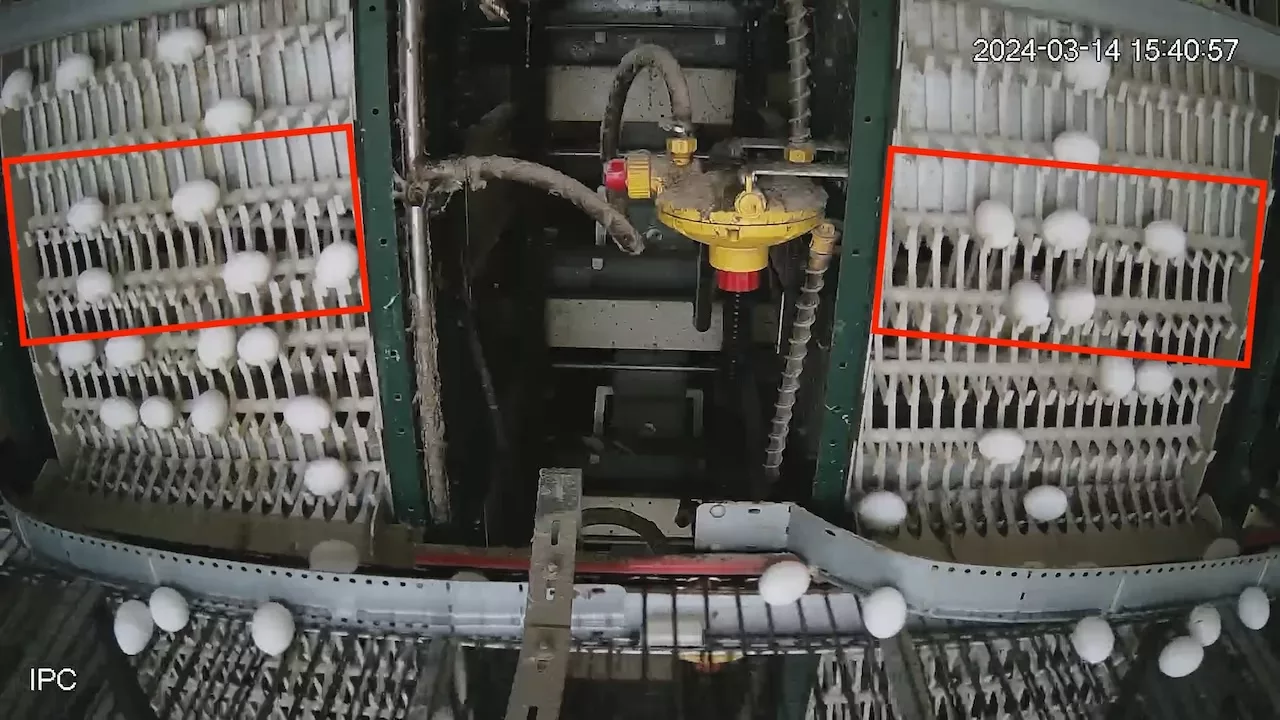

Elevator Type. Eggs move down on a vertical wall

One camera simultaneously counts in two places – to the right and to the left of the battery.

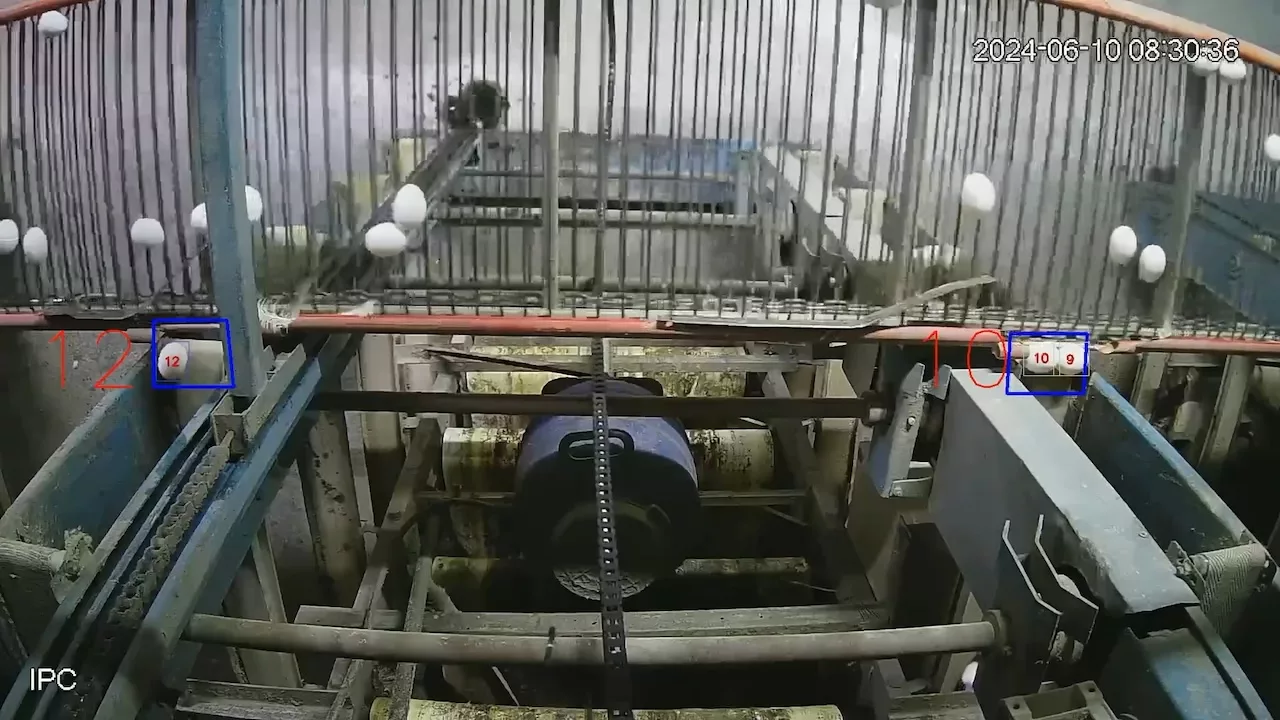

Counting at the outlet of the battery in the sleeves

One camera simultaneously counts in two places – to the right and to the left of the battery.

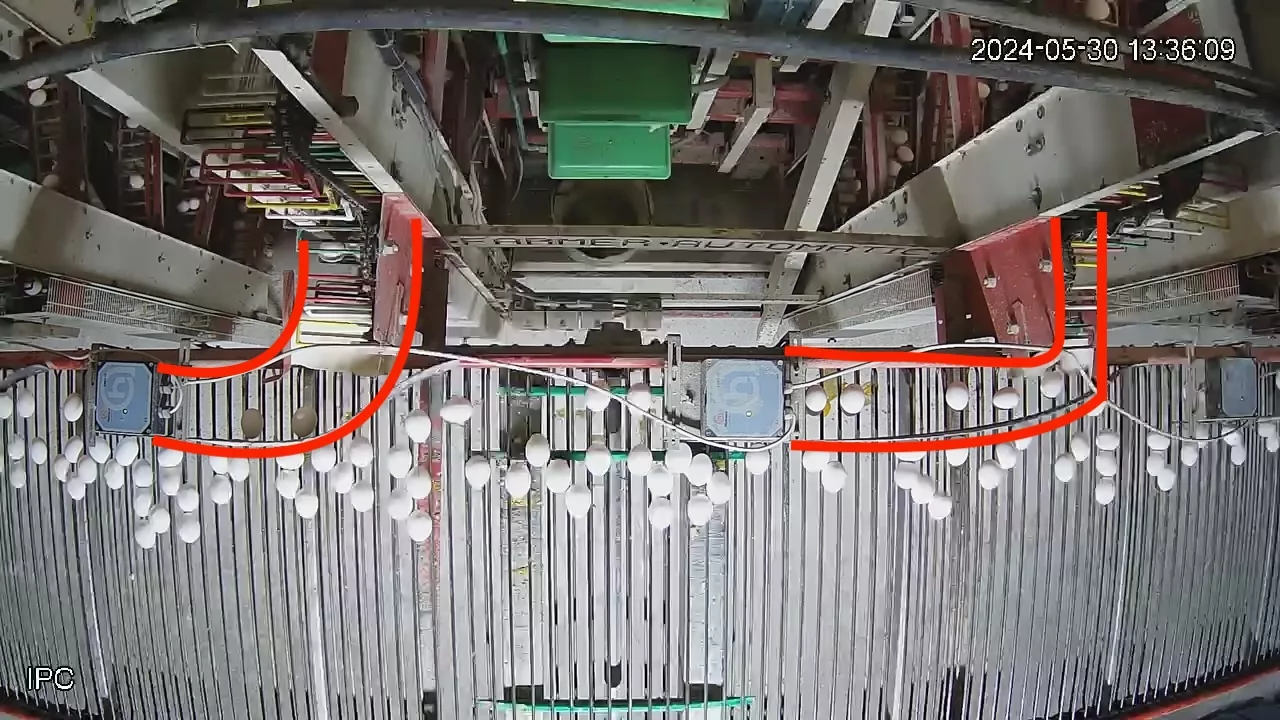

Lift Type

Lift systems can be used for nests with multiple levels. Eggs are collected simultaneously per level in all rows. The camera is mounted directly on the main conveyor, which rises up and down.

One camera simultaneously counts in two places – to the right and to the left of the battery.

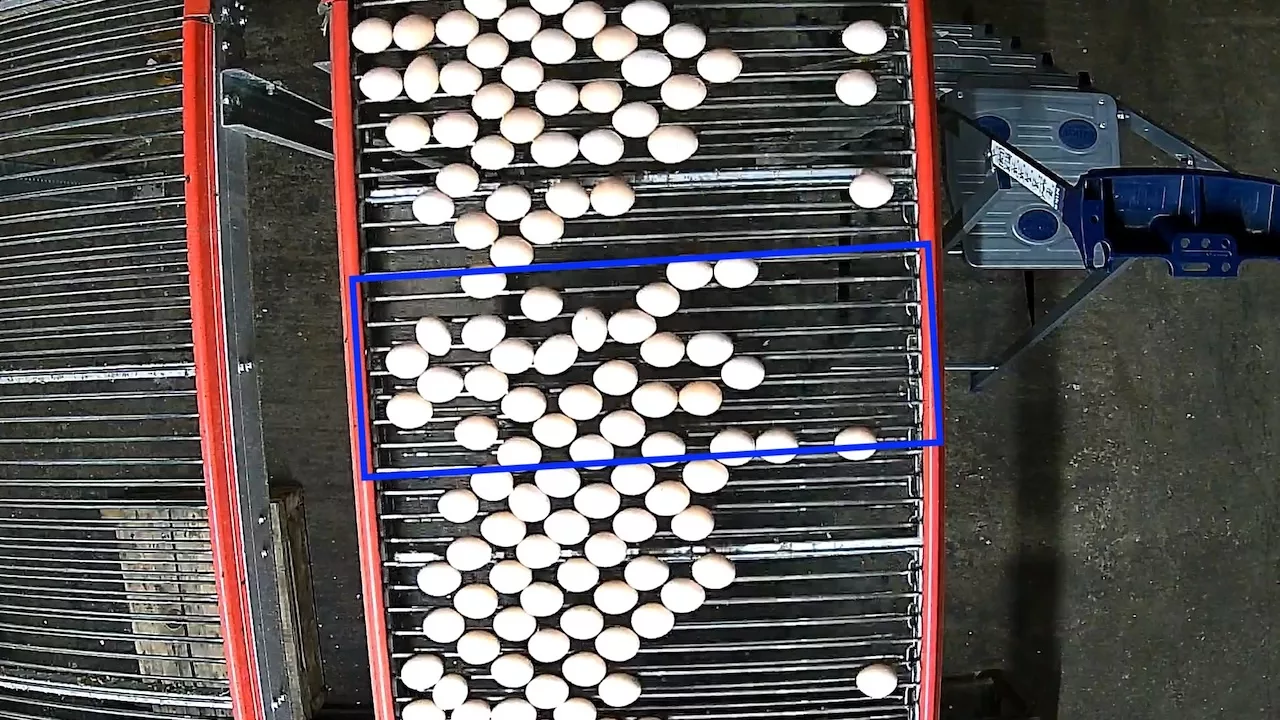

Counting on vertical, rod or curve conveyors

This is usually the main stream where the eggs are moving, also called anaconda.

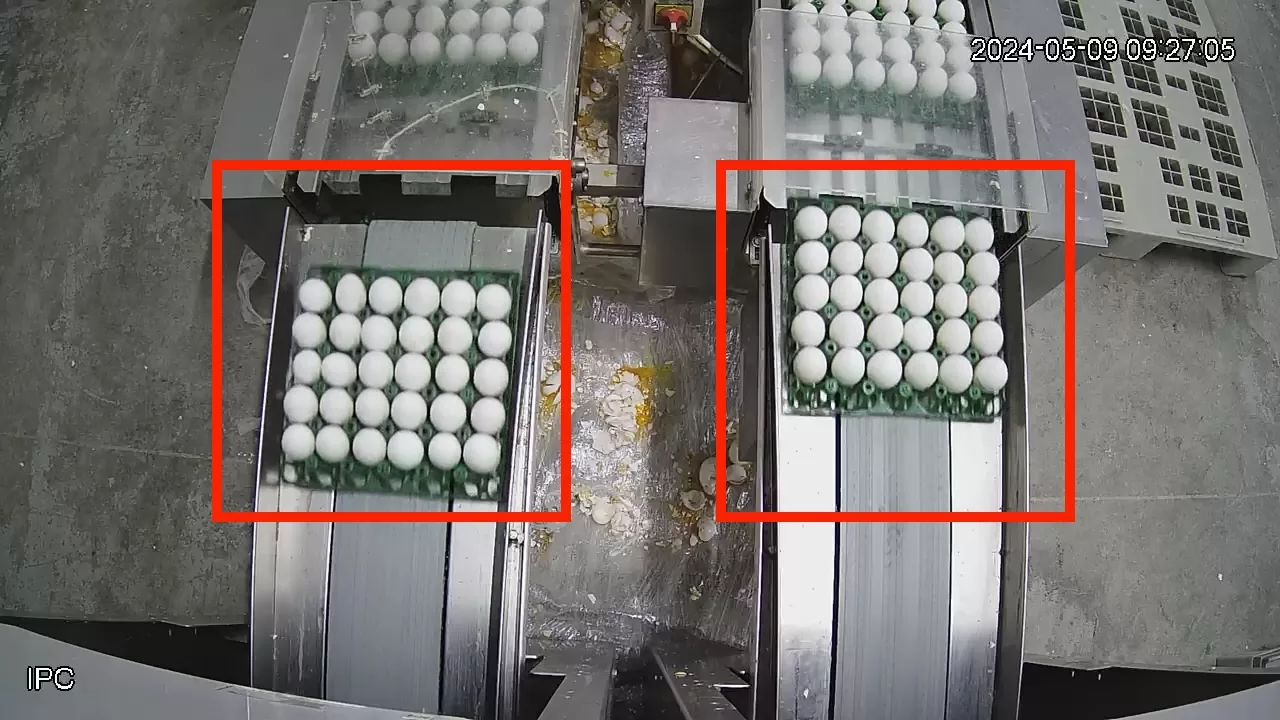

Counting eggs in trays at the packaging stage

Usually in carton or plastic egg boxes.

Counting not only white but brown eggs

Without any additional settings. Any camera with our program can count both white and brown eggs with 99.9% accuracy.

Counting not only chicken eggs, but also quail eggs

With any IP-camera without any additional settings our program can count also quail eggs.

Do you also want to set up detailed egg counting at your poultry farm?

Write to us at info@camcontador.com