Product quality control in manufacturing: how computer vision works in real workshops

Summary

Customers. Industrial enterprises from various sectors: a bread factory, an aluminium container manufacturer, a poultry farm.

Task. Introduce video surveillance in areas where manual quality control is insufficient: count products, record deviations, and provide timely warnings about the risk of defects and malfunctions.

Result. CamContador provides objective data in real time, reduces the workload on staff and identifies problems on the lines before they turn into downtime, returns and complaints.

What’s wrong with traditional quality control

Quality control in manufacturing almost never looks like it does in the regulations. In documents, it is described as a sequential and controlled process: incoming inspection, operational control, outgoing inspection, recording of results, corrective actions. In reality, however, production is a continuous flow of operations, shifts, retooling, human factors, and many situations that cannot be fully anticipated on paper.

It is precisely in these “grey areas” — between operations, when changing modes, starting a line or switching to another product — that a significant portion of defects occur. And not always ones that are immediately obvious. Often, the defect only becomes noticeable once the product has moved further down the chain: to packaging, the warehouse or the customer.

This case study brings together practical examples from companies where quality control has been enhanced using computer vision and video counters. These are not experimental technologies, but working solutions integrated into existing production processes.

Quality control in the production process: why manual control is not enough

In most manufacturing processes, quality control during operations is formally assigned to people.

Decreased attention span. The operator watches the line, the foreman is responsible for the section, and the technologist analyses the reports. This system works if the production flow is relatively small and defects can be eliminated fairly quickly by hand.

When the line is running continuously and the speed and volume of production are increasing, manual control loses its reliability. This is not because people are doing their jobs poorly, but because humans are physically incapable of maintaining the same level of attention throughout an entire shift. This is especially true in monotonous operations, where deviations are rare but can have serious consequences.

Subjectivity of assessments. A separate complication is defects that cannot be clearly assessed “by eye.” These include product temperature, minor damage to packaging materials, and instability in shape or colour that are on the verge of being acceptable. In such cases, the decision depends on the subjective assessment of a specific person each time.

Computer vision is integrated precisely at these points. It does not replace the technologist or operator, but takes on the role of a continuous observer that records deviations from the specified parameters and signals them in a timely manner.

Technical background: how computer vision is used for quality control

All of the projects discussed below use the same basic approach.

Continuous product analysis. The camera is installed in an area where the entire product flow passes and where it is possible to continuously observe each product — from the required angle and under constant shooting conditions. This could be the line exit, the area after a technological operation, or the area before packaging.

The live video stream is analysed by video counter algorithms trained to recognise specific deviations: product defects, changes in shape and colour, temperature anomalies, and other signs that can be used to judge product quality.

Object Detection technology. These tasks are based on Object Detection technology, which recognises and classifies objects in a frame. The algorithm does not simply record movement in the surveillance area, but works with specific objects: it identifies individual items in the general flow and compares them with specified quality criteria.

However, CamContador is not always used specifically as a “counter”. In some cases, counting production is not required at all. It is much more important to detect the deviation itself in a timely manner and transmit the signal to the operator’s monitor or to the conveyor control system.

Integration with equipment. To connect the video counter to the conveyor, an intermediary device is used — a discrete output module with an Ethernet interface and Modbus TCP protocol support. It receives commands from the programme and activates a light or sound alarm, notifying the operator of the need to check the section.

If conveyor movement needs to be controlled, the circuit is built using a magnetic starter or frequency converter. In this case, the module sends a control signal, and the starter or converter performs the required action — turns the conveyor on, off, or changes its speed.

This approach allows computer vision to be integrated into the existing infrastructure of the enterprise without restructuring familiar processes or changing production management logic.

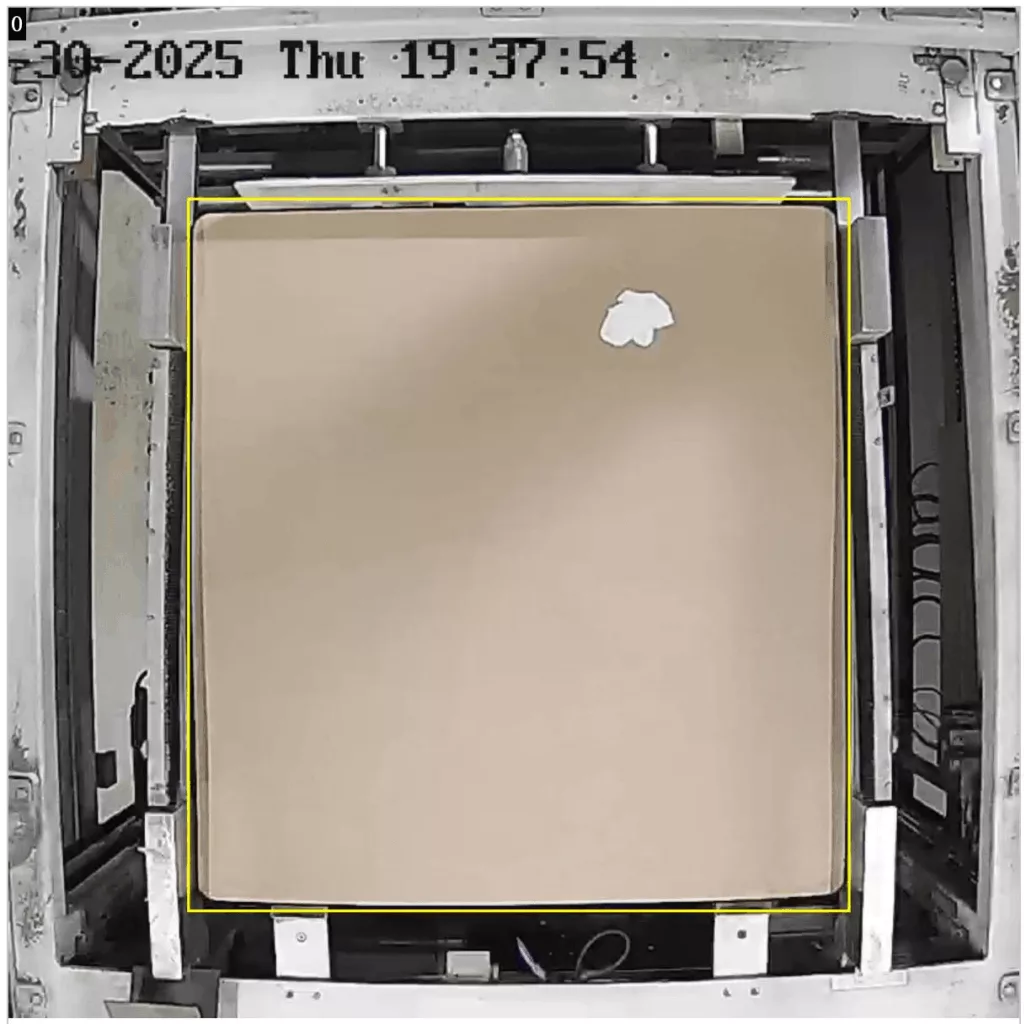

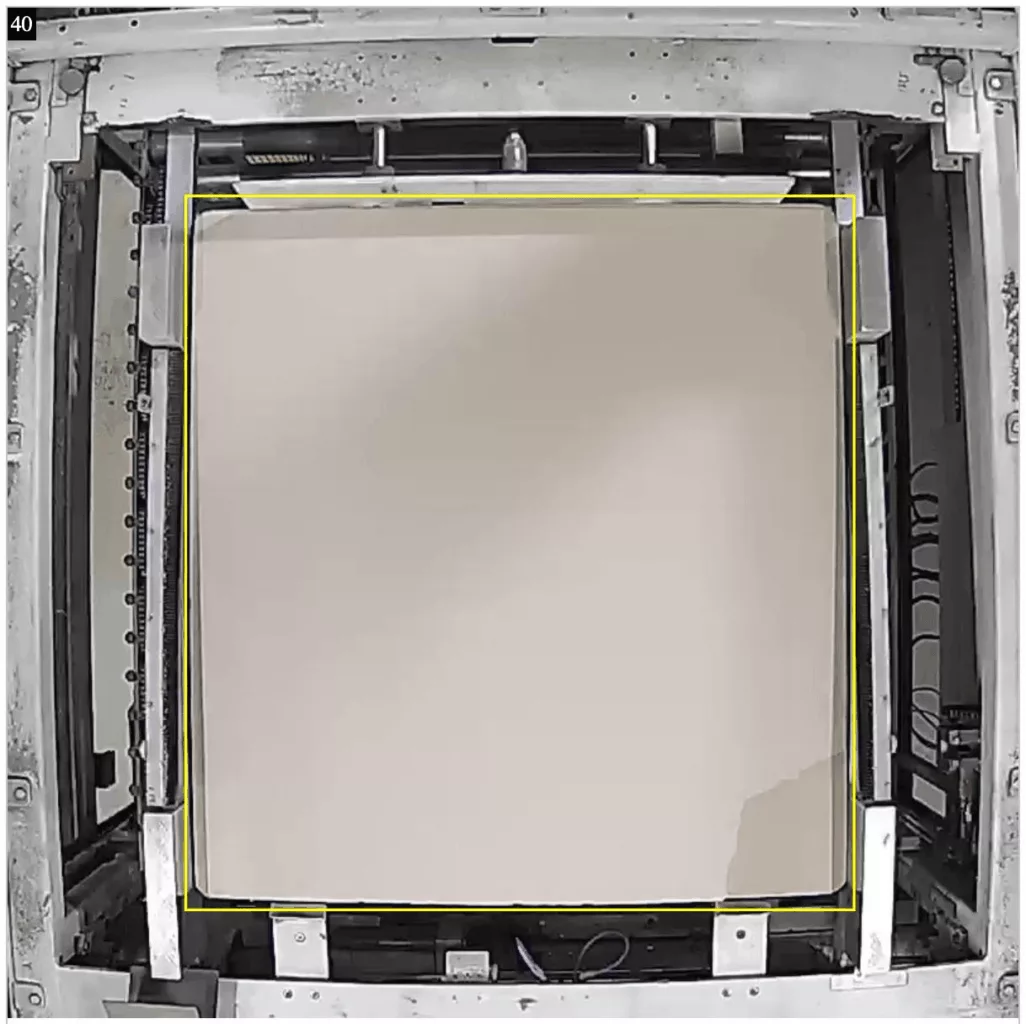

Case 1. Quality control of packaging cardboard in the production of aluminium cans

Situation. An aluminium can manufacturing company encountered a problem related to the quality of packaging cardboard. The cans are stacked on pallets in layers, and each subsequent layer is separated from the one below by cardboard. The automatically assembled pallet is sent further along the production line to the customer’s filling line. It is physically impossible to manually check each layer inside the pallets.

The main difficulties encountered by the company were debris on the surface of the cardboard and torn edges. At first glance, such defects may seem insignificant, but in reality they pose serious risks.

If the edge of the carton is damaged, the can may lose its support, fall out or tip over during transport or feeding to the line. Debris on the surface of the carton moves along with the cans to the filling line, entering the working area of the equipment. In such cases, there is an increased risk of damage to customers’ equipment and subsequent complaints.

Task. Within this section, quality control focused on specific risks:

- presence of large debris on the surface of the packaging cardboard;

- significant damage to the cardboard, which could cause the box to lose its support.

Solution. To solve the problem, a computer vision system was implemented that analyses the surface of the cardboard before it is sent for packaging. The algorithms are configured to detect only critical defects. Minor scratches, dents or insignificant contamination are ignored as they do not affect the stability of the pallet.

Result. When a defect is detected, the system emits an audible and visual signal. This allows staff to intervene promptly: remove debris or replace cardboard, thereby minimising the likelihood of further equipment failure on the filling lines.

See also: Recognition of Upside-Down Cans with Conveyor Line Stop

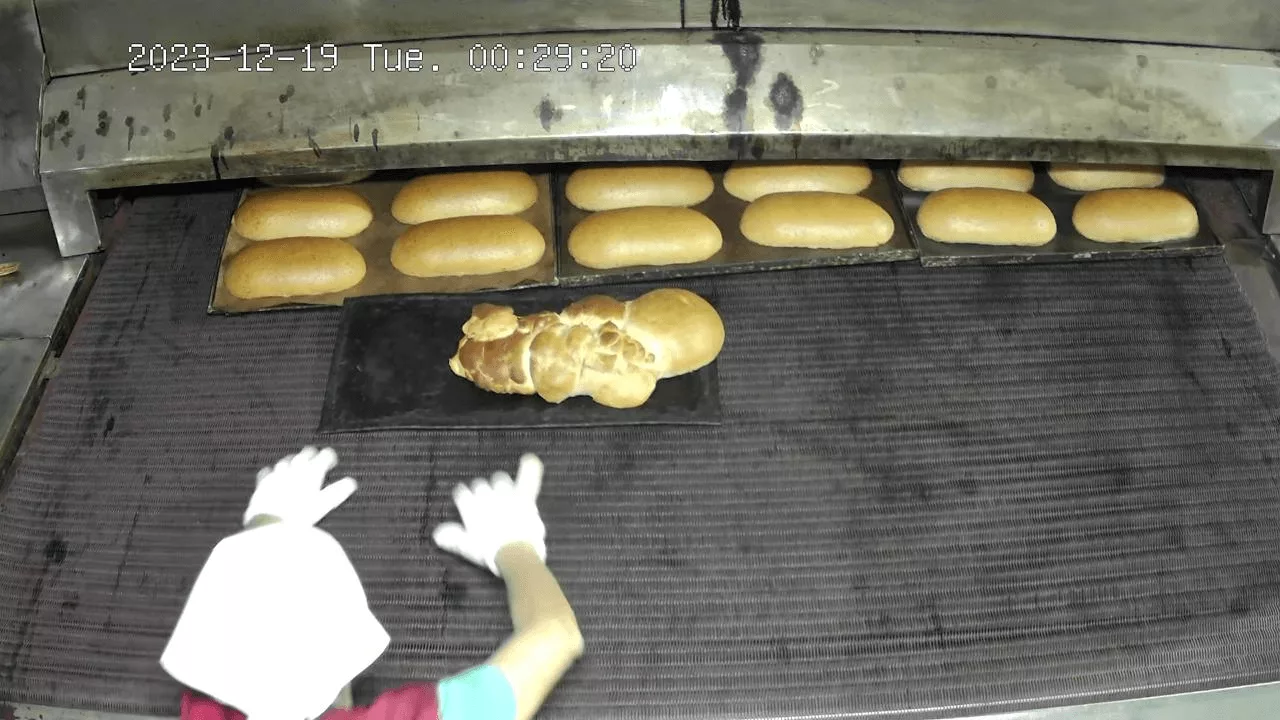

Case 2. Quality control of bakery products

Situation. At a bakery, one production line produces up to 10 types of bakery products. It was important for the enterprise to accurately understand the actual quantity of each type of product manufactured and to take into account the waste that occurs during the production process.

The problem was particularly acute when changing bread varieties: when switching from one type of bread to another, a small amount of dough from the previous variety remains in the oven nozzles. These residues come out with the new batch, resulting in deformed products that do not meet standards. Formally, the products come out of the oven, but in fact they are defective.

Previously, such defects were not always accounted for correctly, which led to discrepancies between raw material consumption and the quantity of finished products.

Task. In this case, it was important for the company to:

- take into account the entire actual output from the furnace;

- to see defects arising from a change in the recipe;

- compare the number of products manufactured with the consumption of raw materials.

Solution. The solution was to install a video counter at the oven outlet. The system records all production output in real time, distinguishes between different types of bread, and counts both acceptable products and rejects. It counts absolutely everything that comes out of the oven, without requiring manual verification.

Result. Accumulated data can be summarised for any period — hour, shift, day, week or month. This approach gives managers an objective picture of production with the necessary detail on output and rejects. As a result, it became possible to compare the actual volume of production with the consumption of raw materials and to understand exactly at what stage losses occur.

See also: How we set up bread counting and recognition on the conveyor belt with a video camera

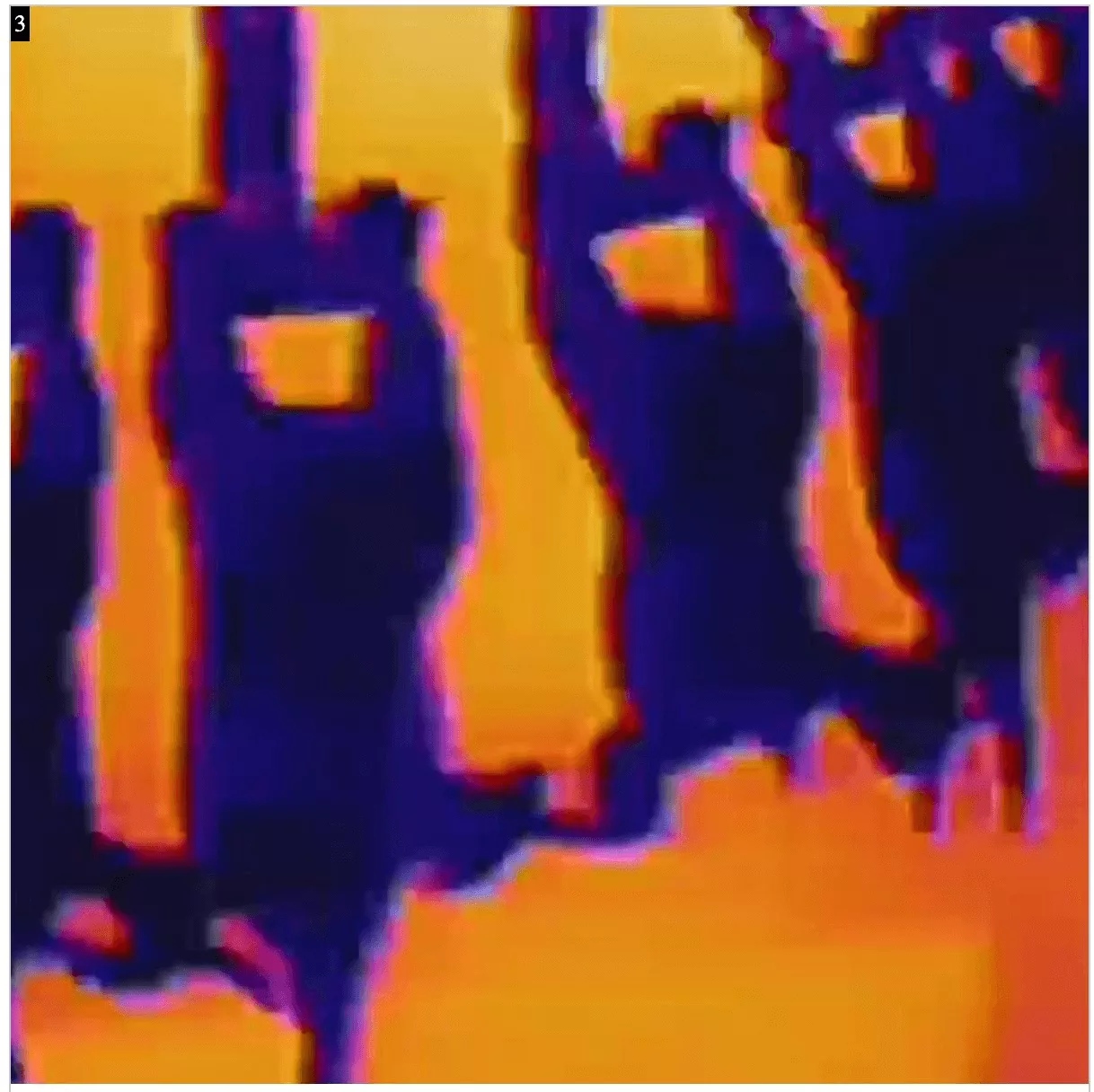

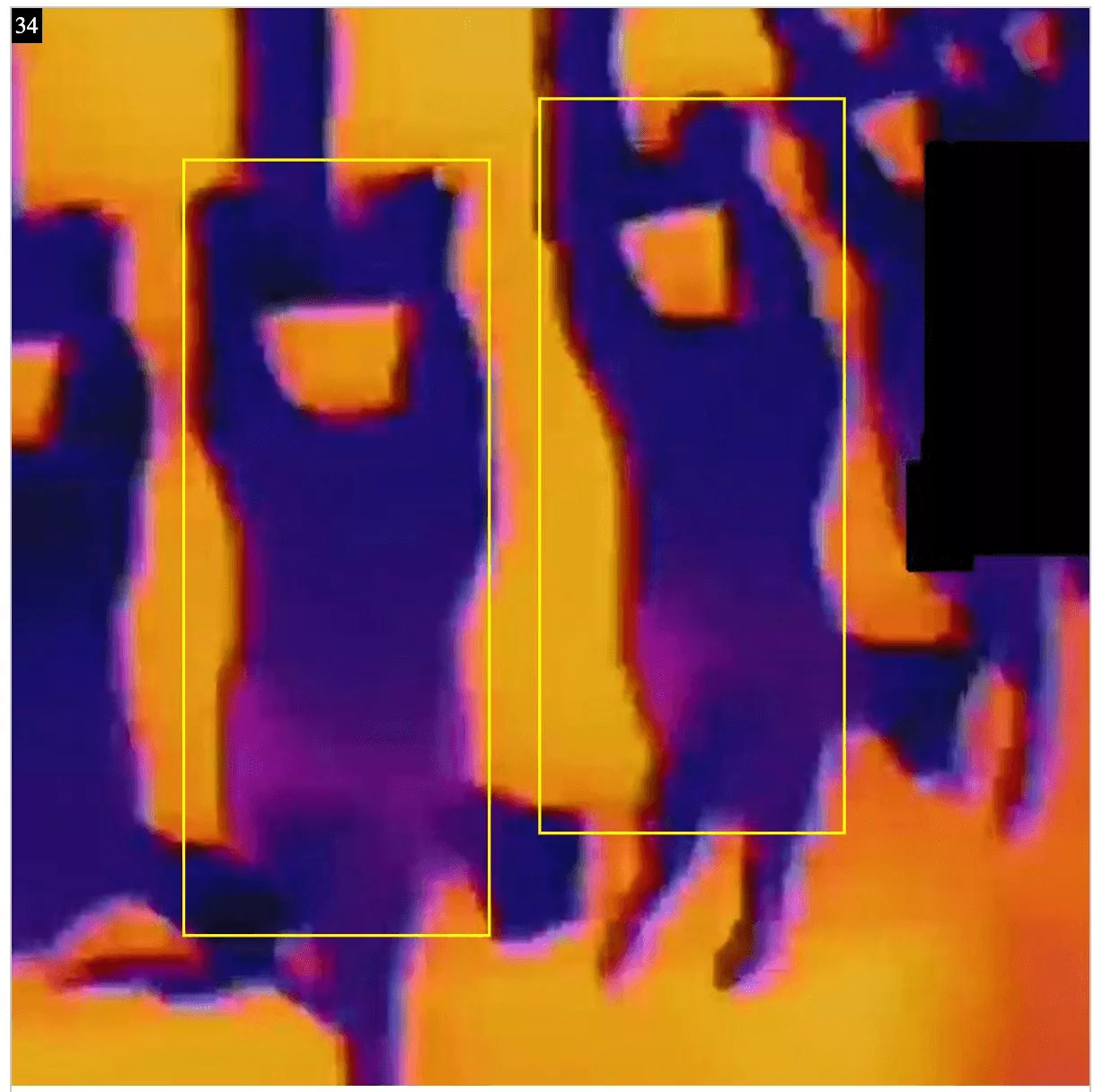

Case 3. Quality control of poultry carcass freezing using a thermal imager at a poultry farm

Situation. At a poultry farm, the quality control task was related to maintaining the temperature regime. After passing through the cold store, the poultry carcasses must be completely frozen. However, when conditions changed — for example, due to an increase in the weight of the carcasses or uneven operation of the refrigeration equipment — some of the products could remain partially frozen.

It is impossible to visually identify such deviations. Even an experienced specialist is unable to assess the temperature of a carcass “by eye”. At the same time, poorly chilled products entering packaging and further logistics pose serious risks. Pockets of microbiological activity may remain inside such carcasses. This increases the likelihood of spoilage, food poisoning among consumers, and subsequent claims from retail chains and regulatory authorities.

Task. Quality control in this project was built around two tasks:

- monitoring the temperature of poultry carcasses after refrigeration;

- timely notification of staff about the appearance of defects.

Solution. A thermal imaging camera connected to a computer vision system was used to solve the problem. Algorithms analyse the temperature spectrum of carcasses and identify deviations from the required condition.

Result. When the system detects carcasses with elevated temperatures, a signal is sent to the staff. This allows them to check the operation of the cold room in a timely manner and adjust the settings without waiting for defective products to accumulate.

See also: Egg counting in a poultry farm: 14 production units, 114 cameras and 207 counting zones

The general logic of applying computer vision in quality control

The cases examined relate to different industries and address different challenges, but they share a common approach.

Continuous monitoring. Computer vision is used as a continuous monitoring tool that works alongside staff and complements their work.

Such systems do not tire, do not get distracted, and analyse every second of the video stream with equal attention. They are particularly useful at those points in the process where the cost of error is high and manual control is unreliable or impossible.

Enhanced control measures. CamContador does not make management decisions. It records deviations and signals them. Then people get involved — the operator, foreman, and technologist. This approach does not require abandoning existing quality control processes. On the contrary, video analytics fits seamlessly into them and strengthens areas that were previously “blind spots”.

In practice, computer vision in quality control works as an additional level of protection. It allows you to notice in time that the process is starting to deviate from the norm and intervene when it is still possible to do so calmly, without emergency production stoppages and financial losses.

What in the end

- Product quality control in manufacturing works more effectively when it is based not only on regulations and reports, but also on objective real-time data.

- CamContador video analytics and video counter enable you to accomplish tasks that are difficult or impossible to perform manually: continuous process monitoring, timely detection of deviations, and early response to changes in line operation.

- For many enterprises, the introduction of video analytics is a logical step in the development of a quality control system — as the speed and complexity of the production flow increases, manual control objectively ceases to provide the same accuracy throughout the process.

- The video counter reduces the workload on staff, while the responsibility for decision-making remains with employees: the system acts as a source of operational data and signals any deviations.

If you have any questions about product quality control using video analytics, please contact us. We will explain how such solutions are applied in enterprises across various industries, what tasks they help to accomplish in practice, and what level of accuracy can be achieved in real production conditions.