Quick and accurate counting of Utensils – spoons, forks and knives

Summary

Client. The company rents out event equipment and over 12 years of operation has completed over 70,000 projects ranging from family celebrations to large-scale festivals for 5,000 guests. Its equipment catalog includes professional restaurant equipment, tableware, cutlery, furniture, and textiles.

Task. After the event it is necessary to quickly receive several thousand pieces of cutlery, count them accurately, and ensure there are no disagreements with the client.

Result. The CamContador video counter made it possible to quickly and accurately count the number of returned forks, spoons, and knives. The program cut the time required for equipment acceptance in half.

Situation

After the event, it is necessary to quickly and accurately accept the equipment returned after rental. After large events, the number of cutlery items (spoons, forks, knives) can reach several thousand. Due to the human factor, errors and disputes with the client arise.

Sometimes a recount was required for clarification. All of this took up not only the employees’ time, but also the customer’s time.

To solve this problem, the company’s management decided to invest in automatic counting using computer vision.

To begin with, they decided to focus on the most common items, namely 40 types of cutlery: knives, forks, and spoons.

Solution

Equipment setup

The client purchased and installed a belt conveyor.

An employee places cutlery on the conveyor belt, and on the other side of the conveyor it falls into a box.

A standard video surveillance camera is mounted above the conveyor.

Dataset collection and neural network training

We needed to include all possible types of knives, spoons, and forks in different positions on the conveyor belt in the neural network’s training set.

To do this, the client placed cutlery on the conveyor belt, and we recorded a video.

We worked with the client to simulate various situations that might occur in real-life work.

For example, the cutlery might be wet, reflecting light, or the conveyor belt might get wet, leaving wet spots and streaks.

The cutlery might arrive dirty, for example, with pieces of cake or other food. Dirty dishes can leave dirt on the conveyor belt.

So, the more unique frames, the better. There’s no need to create artificial situations or interference; the goal is to recreate the actual workflow, the kind of situations that occur in real life.

The client’s employee arranged the cutlery in different positions: in some places, the fork was horizontal, in others, vertical, and in others, at an angle. The same was true for knives and spoons. We ran the system along the conveyor belt several times.

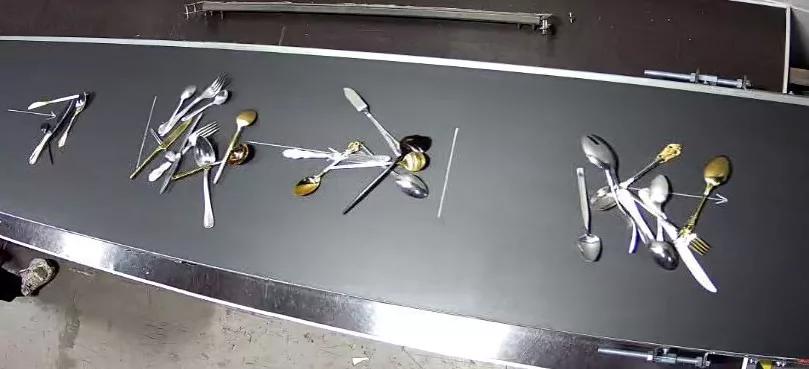

This was the first video, an unrealistic case, in real life they wouldn’t put it like that.

And this layout option is too difficult to recognize and count:

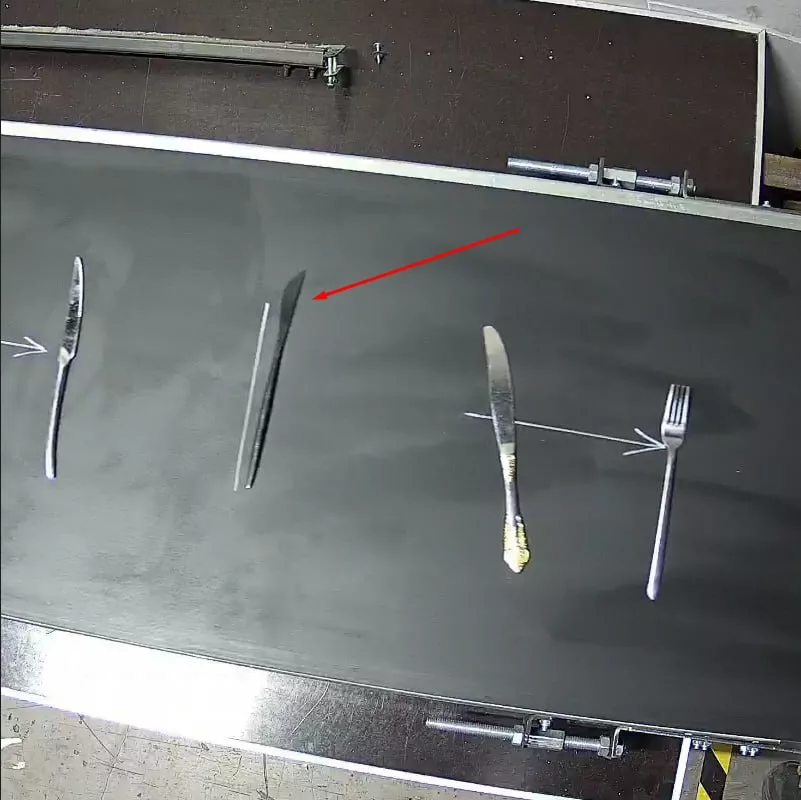

We agreed with the client that we wouldn’t throw everything in a pile, but would place it a short distance apart:

Challenges

Using Oriented Bounding Boxes (OBB)

An oriented bounding box (OBB) is a rectangle that can be rotated to fit an object’s orientation, while a horizontal bounding box (HBB) is a rectangle with fixed, vertical and horizontal sides. OBBs provide a tighter fit for rotated or skewed objects, making them more accurate in applications like aerial surveillance or robotics, while HBBs are simpler but can include unnecessary background when the object is not upright.

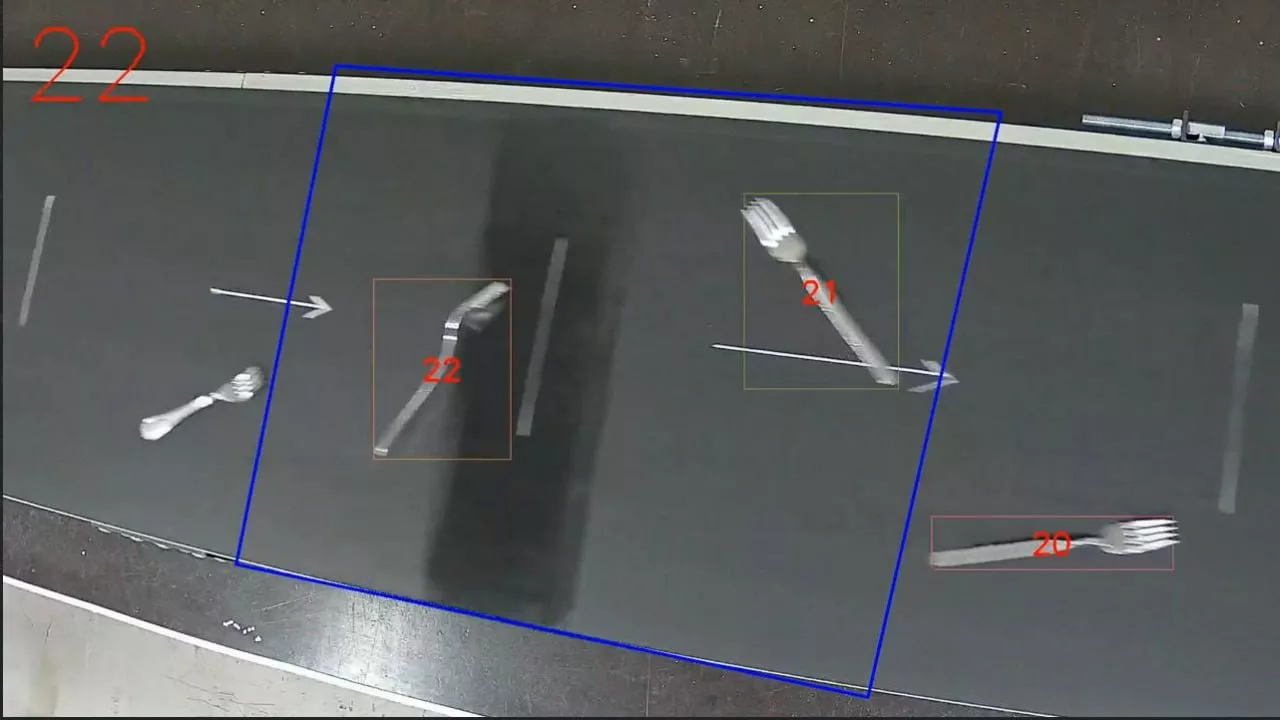

During the project, we realized that employees wouldn’t be able to reliably place forks, spoons, and knives at a sufficient distance from each other to use standard horizontal bounding boxes (HBBs) for object detection. Cutlery can be placed randomly on the belt, sometimes close together, sometimes crisscrossed. In this case, standard horizontal boxes weren’t suitable, so we decided to use Oriented Bounding Boxes (OBBs).

And with the help of new labelling we achieved excellent accuracy.

Dedicated graphics card

We labeled the dataset, trained the neural network, and tried running it on a computer. We discovered that sometimes the processor couldn’t keep up with the frames. The client had allocated an old computer with an i5 10400 processor for the project. This is a relatively old processor, released six years ago.

For this project, we couldn’t use low frame resolution and lightweight neural networks because the tape had stripes and arrows drawn on it, and wet streaks also appeared—and we needed to distinguish them from real forks and knives.

For example, a wet knife left a dark mark on the rubber conveyor belt:

And this is a real black knife:

After a series of experiments, we realized that we needed either a more modern processor or a video card.

GPUs are inexpensive these days, so we recommended the client a GTX 1060 (€100) or an RTX 3050 (€160).

The client purchased an Nvidia GeForce GTX 1060 6GB, and the excessive CPU load issue was resolved.

Arrows painted on a conveyor belt

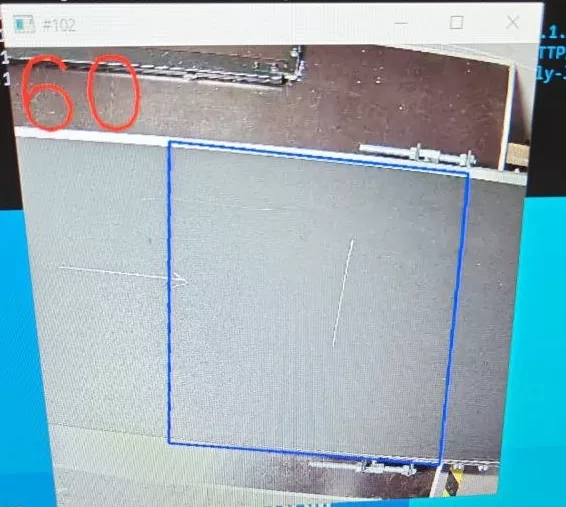

Another interesting detail during the project was that sometimes the counter confused the vertical white stripes on the tape with knives and forks.

The client simply erased them and the problem was solved.

The horizontal arrows did not cause any problems, so they were left as they were.

Having eliminated all the above-mentioned obstacles, we achieved 100% counting accuracy.

The current business process for receiving rented equipment is as follows:

1. Before starting the acceptance procedure, the employee launches the program and turns on the video recording mode.

2. After acceptance the employee turns off the program and generates a quantity report.

3. If the customer has any questions, they watch the recorded video with the counting together.

Results

The time for the acceptance procedure has been cut in half.

Although acceptance is performed by two employees, it doesn’t happen every day or full-time, so the actual time spent is approximately 120 hours per month.

With a salary of €1,500 per month and an employee’s time budget of 150 hours per month, the hourly rate is €10/hour (€1,500/150 hours). Therefore, the monthly acceptance cost is €120 * €10 = €1,200.

After implementing the system, the savings were 50%, or €600 per month.

Project costs:

- Camera and installation: €100

- Computer: €600

- Video card: €100

- Horizontal belt conveyor: €1,000

- CamContador program license: €800

Total: €2,600

The project paid for itself in 5 months.

But it’s not just the money that matters; the most important thing is that the number of errors and customer disputes has decreased. Consequently, customer satisfaction and the NPS index have increased.

Video example of the silverware counting procedure:

Timeline. The project took two months (September–October 2025), including equipment setup, neural network training, and testing.

Team. From CamContador, one specialist worked on the project — an engineer. From the customer’s side — two employees: project manager and IT-specialist.