Egg production plant: counting eggs and controlling conveyor speed using the CamContador video counter

Summary

Customer. Egg Production Poultry Farm. The enterprise operates a fully integrated production cycle, encompassing parent flock management, incubation, pullet rearing, and commercial layer housing. Each year, the facility produces millions of eggs.

Task. Implement an egg counting system using a video camera and integrate conveyor speed control to prevent egg accumulation and damage.

Result. The CamContador video counter performs egg counting with an accuracy of 99.90–99.97% and transmits real-time data every 10 seconds to the frequency inverter control system, which adjusts the conveyor speed to maintain optimal flow and prevent accumulation.

Situation

The poultry farm uses rod-type “Anaconda” conveyors to collect eggs from housing units with thousands of hens in battery cages. The egg flow into the grading facility varies in intensity. Uneven distribution causes accumulation, resulting in cracks and product damage.

Here is how the customer described the situation:

The maximum capacity of the sorting complex is 40 thousand eggs per hour.

Different buildings of the factory feed different quantities of eggs. If all the conveyors work at maximum speed, 50 thousand eggs will arrive at the sorting complex per hour. A collapse will occur, the eggs will fill the sorting machine and crack.

If you limit the speed of all the conveyors, this will not help. There is a time lag between the buildings of the poultry farm and the hens lay eggs at different rates. When there are few eggs in the sorting complex, this is also bad: the operating time increases, and the equipment and employees are idle.

Therefore, the speed of the eggs along the conveyor must be constantly adjusted.

Previously, the farm used an outdated video counter from another supplier. Over time, it no longer met the customer’s requirements: the counter produced errors and did not support conveyor speed control, which prevented the customer from reducing product loss.

This prompted the management to seek a more accurate and modern solution for egg counting and conveyor speed regulation to prevent product damage.

How a bread production plant manages its conveyor using a video camera

Task

The poultry farm management approached us to solve two objectives:

- Implement accurate egg counting using a video camera.

- Integrate the video counter with the conveyor to control the flow speed.

Integration purpose: The counter must regulate conveyor speed to optimize product flow and prevent damage.

When eggs arrive on the conveyor at high intensity and the conveyor speed is too low, “piling” occurs. Eggs press against each other, causing cracks and breakage. In these moments, the conveyor should accelerate to evenly distribute the flow and reduce defects. Conversely, when the egg flow is low, the conveyor speed should decrease to avoid excessive movement speed and ensure consistent egg delivery for sorting and packaging.

Solution

The video counter setup at the poultry farm was completed in a standard timeframe of two days. As mentioned before, implementing egg counters takes less time compared to other product types, since eggs are straightforward objects for counting.

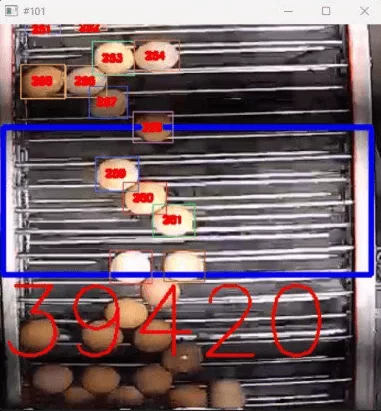

Technical details of egg counting with counter examples

Unlike the project involving 114 video cameras across 207 counting zones, we installed only one camera in the final housing unit, where the egg flow from all production buildings converges.

Our engineer used software tools to crop the frame, excluding unnecessary areas from the shooting zone to ensure a clean counting zone.

Implementing Counting on the Processor

Transition to an industrial computer. The customer acquired an industrial-grade computer in a sealed enclosure, protected against dust, moisture, and contaminants typical for poultry farms. Unlike standard computers that operated with the old counter and quickly became clogged, sealed industrial computers require no regular cleaning. They are highly reliable, functioning maintenance-free for 10 years or more.

However, the downside of this reliability is the hardware configuration. Industrial systems designed for heavy-duty environments are built without fans and discrete GPUs. The challenge is that product counting is typically configured to run on GPUs. That’s why GPUs are a separate requirement in the equipment specifications.

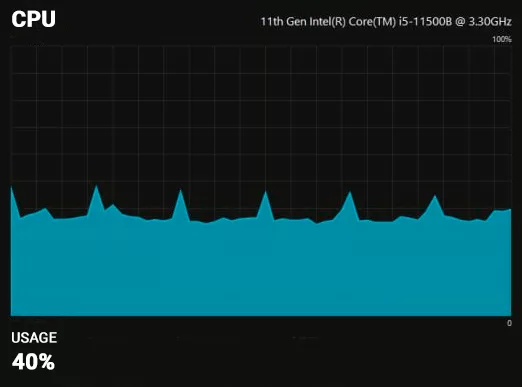

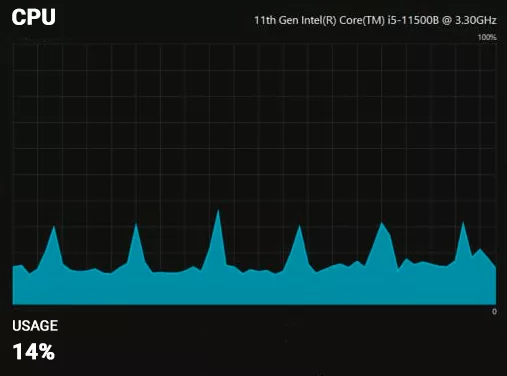

Video processing without a GPU. Unlike typical projects where product counting runs on GPUs, we had to implement egg counting on the CPU for the first time. This approach is slower and could have complicated real-time video stream analysis. To address this, we utilized the Intel OpenVINO toolkit.

The toolkit optimized the egg counting model, eliminated unnecessary operations, and minimized CPU load. As a result, performance improved by 1.5 to 2 times compared to CPU-only processing without OpenVINO. This allowed efficient product counting without the need for a GPU.

Setting Up Conveyor Speed Control

To control the speed of the “Anaconda” conveyor, we integrated the video counter with a frequency inverter connected to the conveyor’s electric motor. This was the most labor-intensive and time-consuming phase of the project.

Initially, there were difficulties transmitting data from the video counter to the inverter. The standard output of the CamContador did not match the control software’s protocol. Our developer modified the video counter software to comply with the control system protocol. Subsequent testing confirmed correct data transmission, and the system became fully operational.

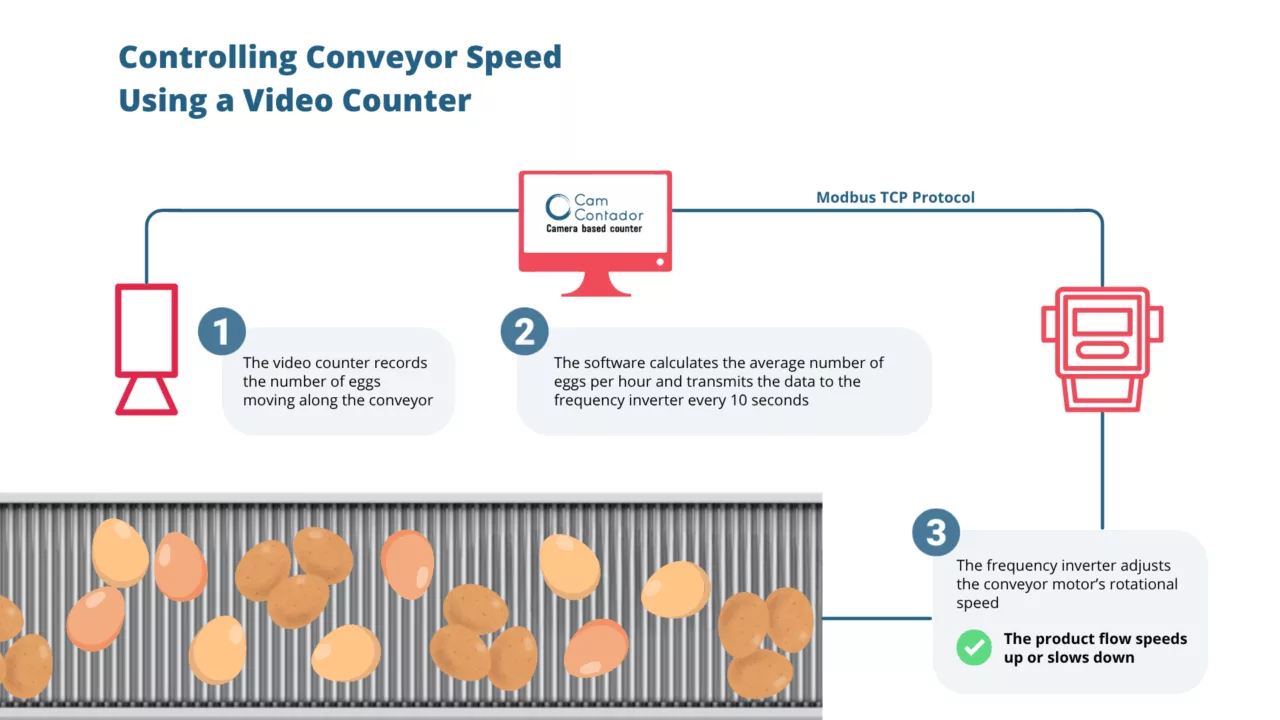

Here is how flow speed control works using a video camera:

- The CamContador video counter detects the number of eggs passing through the camera and calculates the average count per hour.

- Every 10 seconds, this data is sent via Modbus TCP protocol to the frequency inverter control software.

- The frequency inverter adjusts the electric motor’s rotation speed by varying the AC frequency and voltage according to the received data: when egg flow is high, conveyor speed increases; when flow is low, speed decreases.

Results

The customer is satisfied with the performance of the video counter and the conveyor speed control system. Egg counting accuracy ranges from 99.90% to 99.97%. The counting system processes 36,000 to 48,000 eggs per hour.

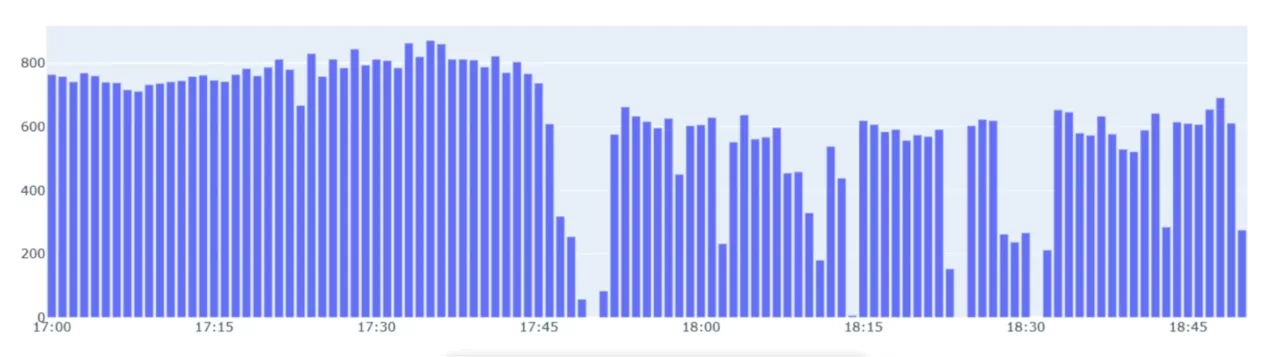

An example of how conveyor speed varies depending on flow intensity:

The poultry farm management plans to increase the number of cameras to four in order to more accurately regulate egg flows in different housing units along each section of the “Anaconda” conveyor.

Project duration: The project lasted three months. Egg counter implementation took two days. The remaining time was spent on software development for conveyor speed control.

Team: On our side, two specialists worked on the project—a systems engineer and a developer. On the customer side, the team included a project manager and an application developer for frequency inverter control.